Introduction

Design for Manufacturing (DFM) Analysis helps engineers create products that are easier and more cost-effective to manufacture. Traditional DFM Analysis in Excel requires building complex checklists to evaluate part numbers, assembly processes, and material selection. While Excel provides a structured way to perform this analysis, it demands significant spreadsheet expertise and manual data entry.

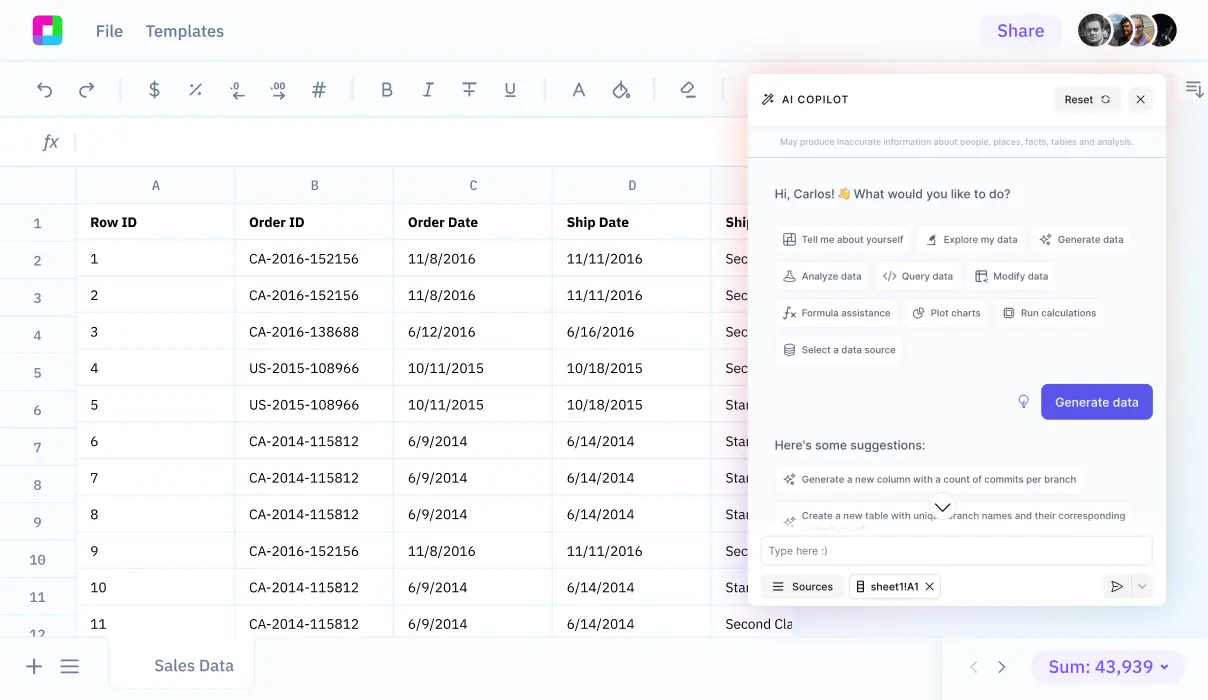

Sourcetable transforms DFM Analysis through conversational AI. Simply upload your manufacturing data and tell Sourcetable's AI chatbot what you want to analyze. The AI assistant helps generate insights, create visualizations, and perform complex calculations without requiring Excel expertise. Whether working with spreadsheets or connecting to databases, you can analyze manufacturing data through natural conversation.

Discover how to streamline your DFM Analysis process using Sourcetable's AI capabilities at https://app.sourcetable.cloud/signup.

Why Sourcetable Is Superior for DFM Analysis

Sourcetable revolutionizes Design for Manufacturing (DFM) analysis by providing an AI-powered spreadsheet that eliminates complex functions and tedious manual work. While Excel requires expertise in formulas and features, Sourcetable's conversational AI interface enables intuitive manufacturing optimization.

Enhanced Data Processing Capabilities

Sourcetable's AI chatbot can analyze manufacturing data of any size through simple file uploads or database connections. This advanced functionality streamlines DFM analysis, which requires optimization of manufacturing processes from early development stages.

Improved Analysis Speed and Efficiency

Instead of wrestling with Excel formulas, Sourcetable's AI understands natural language requests to instantly generate visualizations and reports. This accelerates the transition from design to manufacturing and enables faster decision-making.

AI-Powered Insights

Unlike Excel's manual analysis approach, Sourcetable's AI can automatically identify patterns, generate sample data, and create stunning visualizations from your manufacturing data. This AI-driven analysis leads to more cost-effective and high-quality manufacturing processes.

Simplified User Experience

Sourcetable eliminates the learning curve of traditional spreadsheets by letting users interact naturally with AI. Simply tell Sourcetable what you want to analyze, and it will generate the insights needed to implement effective DFM strategies.

The Benefits of DFM Analysis with Sourcetable

Why DFM Analysis Matters

Design for Manufacturing (DFM) optimizes product design for ease of manufacturing, resulting in better products at lower costs. DFM reduces production complexity, increases efficiency, and improves product quality. It shortens time to market by identifying issues early, enhances product reliability, and reduces production risks. Organizations gain competitive advantages through improved quality, reduced costs, and increased production flexibility.

Sourcetable's Advanced DFM Capabilities

Sourcetable revolutionizes DFM analysis through its AI-powered interface. By simply conversing with Sourcetable's AI chatbot, engineers can quickly analyze manufacturing data and receive instant insights. Whether uploading files or connecting databases, users can evaluate multiple manufacturing scenarios and identify potential issues during the design phase, preventing manufacturability problems and cost overruns.

Advantages Over Excel

Unlike Excel's complex functions and manual processes, Sourcetable lets users analyze data through natural language conversations with AI. Users can create spreadsheets from scratch, generate sample data, and transform raw data into meaningful visualizations by simply telling the AI what they want. This intuitive approach eliminates the need to learn complicated spreadsheet functions while delivering faster, more accurate results.

Collaborative DFM Process

Sourcetable facilitates DFM analysis across all stakeholders, including engineers, designers, contract manufacturers, moldbuilders, and material suppliers. The platform evaluates designs against key principles: process, design, material, environment, and compliance/testing, ensuring comprehensive optimization while meeting customer requirements for pricing, specifications, and scheduling.

DFM Analysis Examples with Sourcetable

Sourcetable, an AI-powered spreadsheet platform, enables effortless DFM analysis through natural language interaction. Simply upload your manufacturing data or connect your database, then tell the AI what analysis you need - from injection molding to CNC machining and various 3D printing processes (DLS, FDM, MJF, and SLA).

A smartphone manufacturer achieved 30% faster assembly times by implementing DFM principles. An automotive parts supplier reduced time-to-market by 40% through DFM and assembly techniques. A medical device company saw defect rates drop 60% after adopting comprehensive DFM guidelines.

Cost and Efficiency Benefits

DFM analysis with Sourcetable's AI assistant delivers measurable cost reductions and efficiency gains. A consumer electronics manufacturer reduced material costs by 25%. An automotive company's dashboard redesign increased recyclable components by 40% while reducing assembly time by 25%. A furniture maker cut material waste by 50% and extended product lifespan by 20%.

Analysis Features

Sourcetable's AI chatbot helps generate detailed DFM reports, visualizations, and data analysis without complex spreadsheet functions. Simply describe your analysis needs, and Sourcetable's AI will create stunning visualizations, perform calculations, and deliver insights from your manufacturing data.

Sourcetable DFM Analysis Use Cases

AI-Assisted PCB Design Analysis |

Upload PCB design data files for AI-driven analysis of design rules, specifications, and manufacturing requirements without complex Excel formulas. |

Cost Analysis Through Natural Language |

Simply ask Sourcetable's AI to analyze manufacturing costs across materials, suppliers, and production variables by connecting your cost data or uploading spreadsheets. |

Production Timeline Assessment |

Use conversational AI to analyze production data, identify potential manufacturing constraints, and generate visualizations of timeline optimization opportunities. |

Automated Trade-off Evaluation |

Let Sourcetable's AI transform your design and manufacturing data into comprehensive comparisons and visual insights for informed decision-making. |

Supply Chain Data Processing |

Upload supply chain data or connect your database to enable AI-powered spend analysis and supplier performance visualization without manual spreadsheet manipulation. |

Frequently Asked Questions

What is DFM Analysis and why is it important?

Design for Manufacturing (DFM) Analysis is a process that ensures a product is manufacturable by simplifying, optimizing, and refining the product design. It's important because it helps create better products at lower costs, and should be done early in the design process when changes can be made quickly and cost-effectively.

What are the key features available for DFM Analysis in modern AI-powered tools?

Modern AI-powered DFM Analysis tools provide automated design feedback, 80+ DFM checks for various manufacturing processes, part thickness analysis with colored heatmaps, and insights derived from millions of parts and tools. They can identify opportunities to reduce tooling complexity and costs while providing specific recommendations for manufacturing improvements.

What are the main DFM considerations for PCB design?

Key DFM considerations for PCB design include setting design rules for DFM constraints, maintaining an 8:1 aspect ratio between hole diameter and via length, ensuring minimum clearances between vias and conductors, using SMD instead of through-hole components when possible, and properly implementing tented vias when needed.

Conclusion

Design for Manufacturing (DFM) analysis traditionally relies on Excel checklists to evaluate factors like part minimization, assembly optimization, and process repeatability. While Excel provides a structured approach through comprehensive checklists, modern AI-powered alternatives like Sourcetable offer enhanced capabilities for DFM analysis.

Sourcetable revolutionizes DFM analysis by replacing complex Excel functions with natural language interactions. Simply upload your manufacturing data or connect your database, then tell Sourcetable's AI chatbot what analysis you need. The platform automatically generates insights, visualizations, and comprehensive analysis of manufacturability and sustainability metrics - no spreadsheet expertise required.

Ready to revolutionize your DFM analysis? Try Sourcetable's AI-powered spreadsheet capabilities at https://app.sourcetable.cloud/signup.