Introduction

Machine Breakdown Analysis helps manufacturers identify, track, and prevent equipment failures that impact production. Traditional analysis involves creating Excel templates to record machine information, breakdown descriptions, root causes, impact assessments, and preventive measures. While Excel templates work, they require manual data entry and complex formulas.

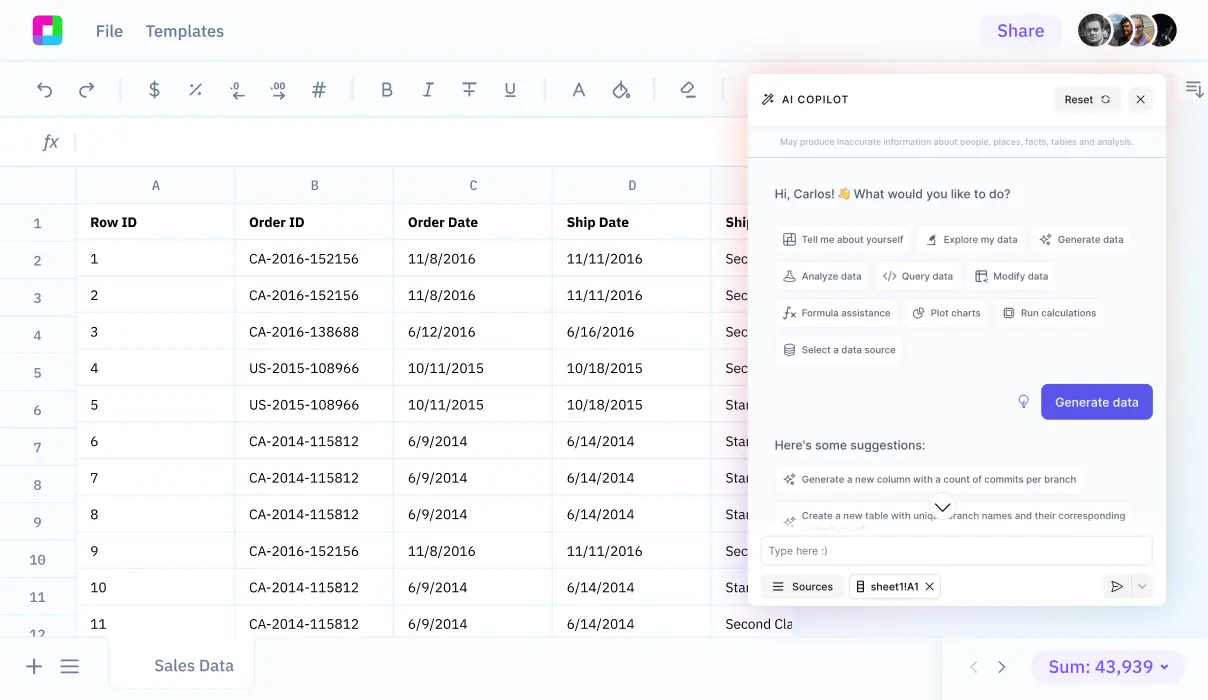

Sourcetable offers an AI-powered alternative that transforms spreadsheet analysis. This AI chatbot-driven platform lets users upload machine data files or connect databases, then analyze breakdowns through natural conversation. Without writing formulas or mastering Excel features, users can instantly generate insights, visualizations, and recommendations by simply describing what they want to analyze.

Learn how Sourcetable's AI-powered spreadsheet revolutionizes machine breakdown analysis through intelligent data processing, visualization, and predictive insights - all through simple conversation.

Sourcetable: The Superior Platform for Machine Breakdown Analysis

Sourcetable transforms machine breakdown analysis by replacing complex spreadsheet functions with conversational AI. Unlike Excel's manual formula-based approach, Sourcetable's AI chatbot lets you analyze machine data through natural conversation, dramatically simplifying the analysis process.

AI-Powered Analysis

While Excel requires expertise in formulas and functions, Sourcetable lets you simply tell its AI what analysis you need. Upload your machine data files or connect your database, and Sourcetable's AI will handle the complex calculations and data processing automatically.

Visualization and Reporting

Sourcetable's AI can instantly transform your machine breakdown data into clear visualizations and charts. Simply describe the insights you're looking for, and Sourcetable will create the most effective visual representation of your data without the need for manual chart configuration.

Simplified Workflow

Sourcetable eliminates the learning curve associated with Excel's complex features. Its conversational interface means anyone can perform sophisticated machine breakdown analysis by simply chatting with the AI, making data analysis accessible to entire teams regardless of technical expertise.

Machine Breakdown Analysis: Benefits and Modern Tools

Benefits of Machine Breakdown Analysis

Machine breakdown analysis provides significant organizational benefits when implemented with a documented maintenance plan. It reduces maintenance and replacement costs by eliminating unnecessary upkeep and consolidating downtime for repairs. The process also minimizes manual labor requirements and simplifies equipment identification for maintenance.

Advanced Analysis with Sourcetable

Sourcetable transforms machine breakdown analysis through its intuitive AI chatbot interface. Simply upload your maintenance data files or connect your database, then tell the AI what analysis you need. The AI handles everything from data processing to visualization, eliminating the need for complex spreadsheet formulas or technical knowledge.

Key Advantages Over Excel

Unlike Excel's complex formulas and manual processes, Sourcetable's AI chatbot creates and analyzes spreadsheets through natural conversation. You can generate sample data, perform detailed analyses, and create stunning visualizations simply by describing what you want. The AI understands your needs and delivers results instantly, making maintenance analysis faster and more accessible.

Analytical Tools Integration

Sourcetable's AI can implement essential breakdown analysis methods like Ishikawa Fishbone Diagrams, Pareto Charts, and the 5 Whys methodology through simple conversation. Tell the AI your analysis goals, and it will generate appropriate visualizations and insights, streamlining the entire maintenance analysis workflow.

Examples of Machine Breakdown Analysis with Sourcetable

Sourcetable, an AI-powered spreadsheet, simplifies machine breakdown analysis through natural language interactions. Upload your machine data files or connect your database, then let Sourcetable's AI create comprehensive analyses and visualizations based on your requirements.

Visualization Types

Simply ask Sourcetable's AI to create the visualizations you need. The system can generate box plots, density plots, bar charts, and scatter plots to analyze equipment performance, all through conversation-based commands.

Analysis Methods

Tell Sourcetable's AI what you want to track - whether it's machine downtime by unit, shift patterns, or categories. The AI assistant can automatically differentiate between planned and unplanned downtime, create Pareto charts for major downtime sources, and analyze departmental metrics.

Predictive Capabilities

Request predictive analyses from Sourcetable's AI to monitor operational parameters and forecast potential failures. The system can implement predictive maintenance suggestions and condition monitoring through simple conversational prompts.

Benefits

Digital machine breakdown analysis reduces downtime, ensures compliance, and increases visibility. The system provides insights to prevent recurring breakdowns while enhancing efficiency and productivity through systematic documentation and analysis.

Machine Breakdown Analysis Use Cases with Sourcetable

Predictive Maintenance Scheduling |

Upload machine performance data to Sourcetable and use natural language commands to analyze equipment trends. Simply ask the AI chatbot to identify maintenance timing patterns and generate preventive maintenance schedules that reduce potential breakdowns. |

Pattern Detection in Equipment Failures |

Connect your maintenance database to Sourcetable and let the AI chatbot discover complex patterns in breakdown data. Tell the AI what insights you need, and it will automatically analyze correlations between operational conditions and equipment failures. |

Downtime Analysis and Cost Reduction |

Import breakdown logs and maintenance cost data into Sourcetable. Ask the AI to create visualizations and reports that highlight frequency patterns, duration trends, and cost impacts of equipment failures to optimize repair schedules. |

Condition Monitoring Dashboard |

Upload sensor data files and ask Sourcetable's AI to create dynamic monitoring dashboards. The AI chatbot can generate early warning indicators and automated alerts for machine degradation, making complex analysis accessible to all staff levels. |

Frequently Asked Questions

What is Machine Breakdown Analysis and why is it important?

Machine Breakdown Analysis is the process of analyzing machine data to understand where and why machines are breaking down. It requires collecting and analyzing downtime data from the shop floor, which can be done manually or automatically. Automatic data collection enables real-time analysis that can help reduce machine downtime.

What types of reports and analysis can be performed for Machine Breakdown Analysis?

Key reports for Machine Breakdown Analysis include equipment history reports, equipment downtime reports, complaints history reports, maintenance work request reports, and equipment statistics reports (such as MTBF and MTTF). The Downtime Pareto report can be used to analyze machine downtime and identify specific causes of failures.

How can Sourcetable's AI assist with Machine Breakdown Analysis?

Sourcetable's AI chatbot can help you analyze machine breakdown data by simply uploading your files or connecting your database. You can then use natural language to ask the AI to analyze trends, create maintenance schedules, identify equipment issues, and generate stunning visualizations of your analysis. Instead of using complex Excel functions, you can simply tell Sourcetable what insights you need, and its AI will handle the analysis for you.

Conclusion

Machine Breakdown Analysis in Excel requires careful tracking of equipment failures, downtime, and maintenance data to identify patterns and improve Overall Equipment Effectiveness (OEE). While Excel templates can help analyze machine breakdowns through formulas and charts, the process demands significant spreadsheet expertise and manual data management.

Sourcetable offers an AI-powered alternative that eliminates the need for complex Excel formulas and manual analysis. Simply upload your maintenance data or connect your database, then ask Sourcetable's AI chatbot to analyze breakdown patterns, generate visualizations, and identify potential equipment issues. The AI assistant handles all the spreadsheet work, from data cleaning to chart creation, making breakdown analysis accessible to everyone.

Ready to simplify your Machine Breakdown Analysis? Try Sourcetable's AI chatbot spreadsheet solution today and let artificial intelligence transform your equipment maintenance strategy.