Introduction

Process Capability Analysis measures how well a process meets specifications by comparing output to specification limits. This analysis calculates Cp and Cpk values to determine process performance and capability. Traditional analysis requires collecting sample data, identifying specifications, calculating means and standard deviations, and determining acceptable deviations.

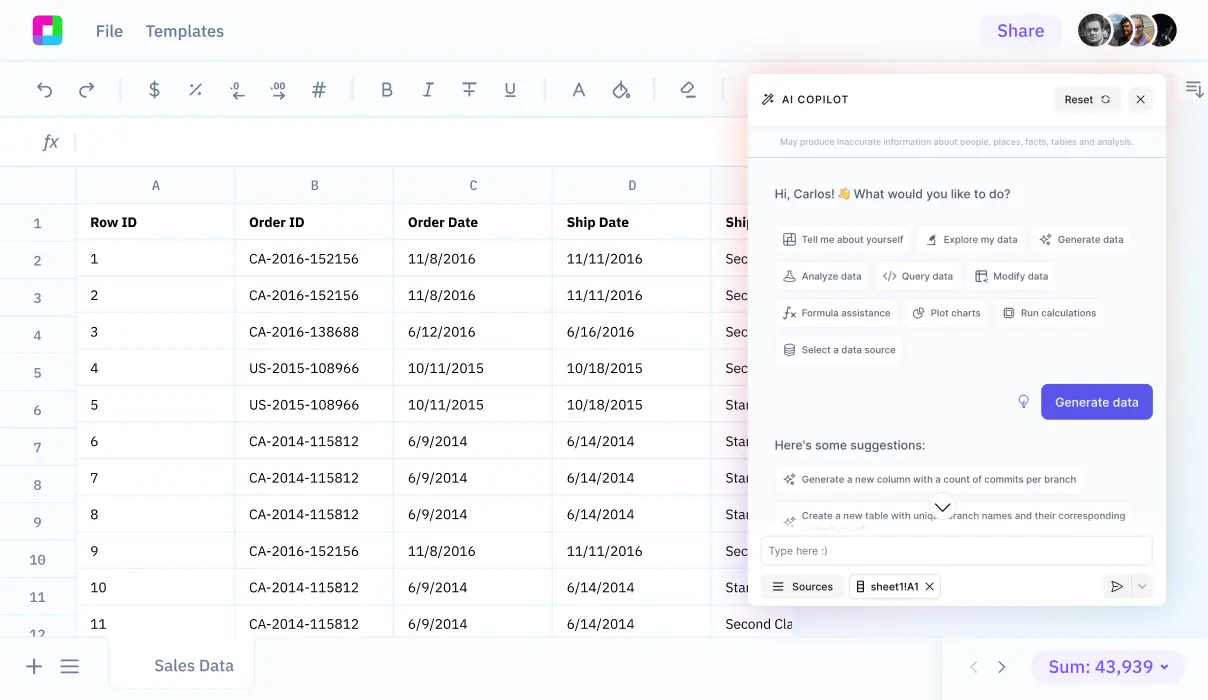

While Excel remains a common tool for Process Capability Analysis through histograms and Cp/Cpk templates, it demands complex formulas and manual calculations. Modern AI alternatives like Sourcetable transform this analysis with conversational AI. Sourcetable's AI chatbot eliminates manual spreadsheet work by automatically analyzing data, generating visualizations, and calculating capability metrics through simple text commands.

Let's explore how Sourcetable's AI-powered analysis simplifies Process Capability Analysis through natural language processing, automated calculations, and intelligent visualization tools.

Why Sourcetable Is Superior for Process Capability Analysis

Process capability analysis requires complex calculations of metrics like Cp, Cpk, Pp, and Ppk to predict and evaluate manufacturing process performance. Sourcetable's AI chatbot eliminates the need for manual calculations and complex Excel formulas by letting you analyze data through natural conversation.

Simplified Analysis Through Conversation

Unlike Excel's function-based approach, Sourcetable lets you analyze process capability data by simply telling its AI chatbot what you want to know. This conversational interface makes analyzing both short-term and long-term process capability metrics accessible to users of all skill levels.

Effortless Data Processing

Sourcetable processes manufacturing data from your uploaded files or connected databases with ease. Whether calculating within-standard deviations for Cpk or overall standard deviations for Ppk, Sourcetable's AI handles the complexity while you focus on insights.

AI-Powered Visualization

While Excel requires manual chart creation, Sourcetable generates stunning visualizations through simple conversation. Tell the AI what insights you need, and it automatically creates the right visualizations to help you understand process capabilities and identify improvements.

Benefits of Process Capability Analysis with Sourcetable

Why Process Capability Analysis Matters

Process capability analysis is a crucial metric for improving product and service quality. It identifies areas for improvement, reduces waste and mistakes, and increases customer satisfaction. Organizations use it as a benchmarking tool to compare performance against industry standards, driving continuous operational improvement.

Advanced Analysis with Sourcetable

Sourcetable, an AI-powered spreadsheet solution, revolutionizes process capability analysis through natural language interaction. Instead of complex formulas and manual analysis, users simply tell Sourcetable's AI chatbot what they want to analyze. The platform handles data of any size through file uploads or database connections, making analysis faster and more intuitive than traditional spreadsheets.

Data Visualization Benefits

Sourcetable excels at transforming complex data into stunning visualizations through simple conversation with its AI. These visualizations reveal patterns and trends, improve data understanding, and enhance decision-making. The AI-driven approach eliminates the need for manual chart creation while ensuring professional-quality results.

Advantages Over Excel

Unlike Excel's complex functions and formulas, Sourcetable allows users to perform advanced data analysis through natural language commands. Its AI chatbot can create spreadsheets from scratch, generate sample data, and perform sophisticated analysis without requiring technical expertise. This conversational approach makes data analysis more accessible and efficient than traditional spreadsheet tools.

Process Capability Analysis Examples with AI-Powered Sourcetable

Process capability analysis becomes effortless with Sourcetable's AI chatbot interface. Simply upload your process data or connect your database, then tell the AI what analysis you need. The platform handles both short-term and long-term capability forecasting through natural language commands rather than complex formulas.

Short-Term vs Long-Term Analysis

Short-term metrics Cpk and Cp use within standard deviation, while long-term metrics Pp and Ppk utilize overall standard deviation. For example, an ice cream parlor maintaining temperatures between -15°C and -35°C with a mean of -25°C and standard deviation of 2°C can calculate process capability index using (USL - LSL)/(6σ).

AI-Enhanced Capability Analysis

Sourcetable's conversational AI interface eliminates the need to master complex spreadsheet functions. Simply describe your process capability analysis needs, and the AI will generate appropriate calculations, visualizations, and insights from your data.

The AI automatically handles capability metrics for both sample data (Cp, Cpk) and population data (Pp, Ppk). This natural language approach makes process capability assessment accessible to users of all skill levels while delivering comprehensive analytical insights.

Process Capability Analysis Use Cases with Sourcetable AI

Real-Time Manufacturing Quality Analysis |

Upload manufacturing data files or connect databases to Sourcetable to analyze process capability. Ask the AI chatbot to generate control charts and calculate process capability indices |

Visual Quality Analysis |

Upload quality data files to Sourcetable and let the AI transform them into stunning visualizations. Ask the AI to create charts showing process performance and capability metrics. Get clear visual insights about manufacturing processes through natural conversation. |

Automated Report Generation |

Tell Sourcetable's AI chatbot to create comprehensive process capability reports. Let the AI handle data analysis, chart creation, and result summarization. Get professional reports by simply describing what you want to analyze. Production Process QualificationUpload historical process data and ask Sourcetable's AI to help qualify new manufacturing processes. Let the AI identify patterns and calculate statistical metrics through natural conversation. Get instant insights about process performance without writing complex formulas. |

Frequently Asked Questions

What is Process Capability Analysis and why is it important?

Process Capability Analysis is a method used to determine if a process can meet customer specifications. It helps identify performance problems, shows what to do about those problems, and determines how well a stable process meets specifications. The analysis provides a comprehensive overview of process stability, normality, and capability.

What outputs and visualizations does Process Capability Analysis provide in Sourcetable?

Process Capability Analysis in Sourcetable provides multiple outputs including: a histogram with specifications and normal curve overlay, appropriate control charts based on data subgrouping, a capability plot comparing process spread with specifications, a run chart for assessing observation independence, a normal Q-Q Plot for normality assessment, and numeric outputs including assumption checks, capability statistics, percent out-of-spec, yield percentage, and process sigma level.

How can I perform Process Capability Analysis in Sourcetable?

You can perform Process Capability Analysis in Sourcetable by simply uploading your process data file or connecting your database, then using Sourcetable's AI chatbot to analyze your data. Just tell the AI what analysis you want to perform, and it will automatically generate the appropriate charts, reports, and statistical analyses. No coding or complex Excel functions are needed - Sourcetable's AI does all the work for you.

Conclusion

Process Capability Analysis helps manufacturers identify performance problems and meet customer requirements by calculating Cp and Cpk metrics. Traditional Excel tools like QI Macros offer capability studies through histograms and templates, but these methods require manual effort and expertise.

Sourcetable provides a better way through AI. Instead of wrestling with Excel functions and formulas, you can simply tell Sourcetable's AI chatbot what process data you want to analyze. Upload your data and let the AI handle the analysis, visualizations, and calculations automatically. Try process capability analysis with AI at https://app.sourcetable.cloud/signup.