Introduction

Stack Up Analysis is a critical engineering process that involves three key steps: Prepare, Stack, and Adjust. While traditionally performed in Excel using tolerance stack up spreadsheets, modern AI alternatives offer enhanced capabilities. Sourcetable, an innovative AI-powered spreadsheet platform, replaces complex Excel functions with natural language interactions for seamless analysis.

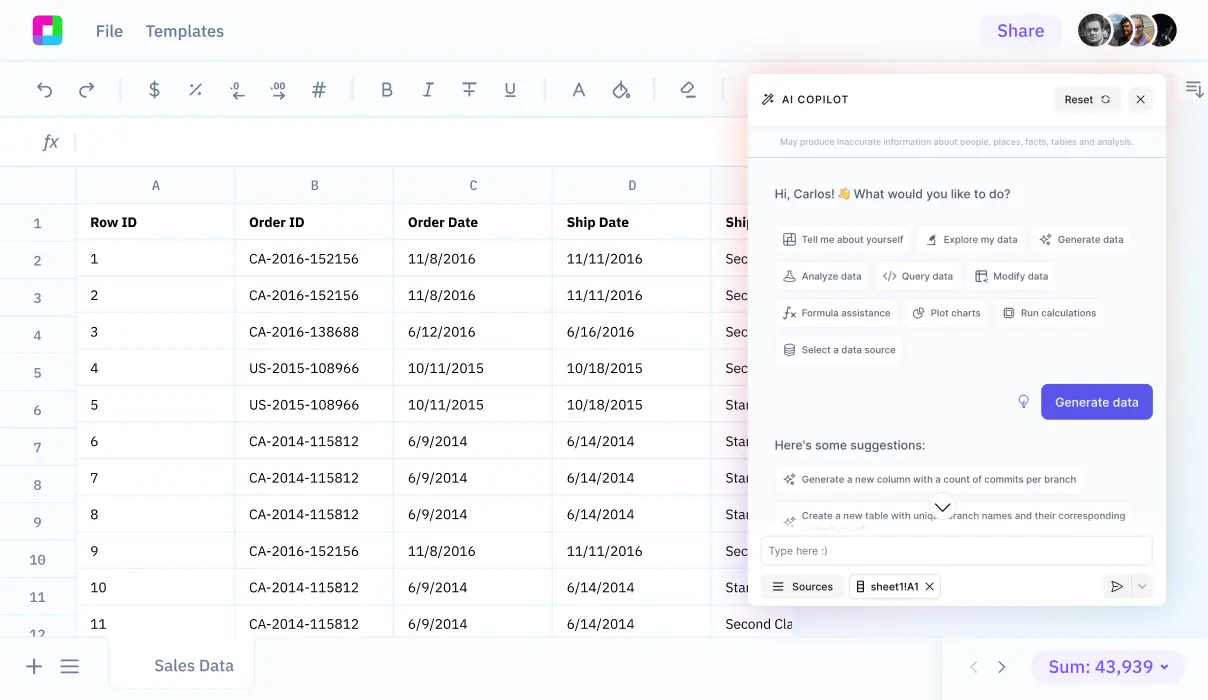

Unlike traditional spreadsheets, Sourcetable features an AI chatbot that automates spreadsheet creation, data analysis, and visualization. Users can simply upload their files or connect their database and tell the AI what analysis they need. For Stack Up Analysis, this means engineers can focus on decision-making while Sourcetable's AI handles the technical complexities of data processing and formula creation.

Learn how to leverage Sourcetable's AI features for efficient Stack Up Analysis at https://app.sourcetable.cloud/signup.

Why Sourcetable Is Superior for Stack Up Analysis

Sourcetable revolutionizes tolerance stackup analysis by combining AI-powered conversational capabilities with spreadsheet functionality. Unlike Excel's complex formulas and manual processes, Sourcetable lets you interact with a chatbot to analyze tolerance data, perform both worst case ∑T and RSS √∑T² calculations, and generate insights through natural conversation.

Automated Visualization Advantages

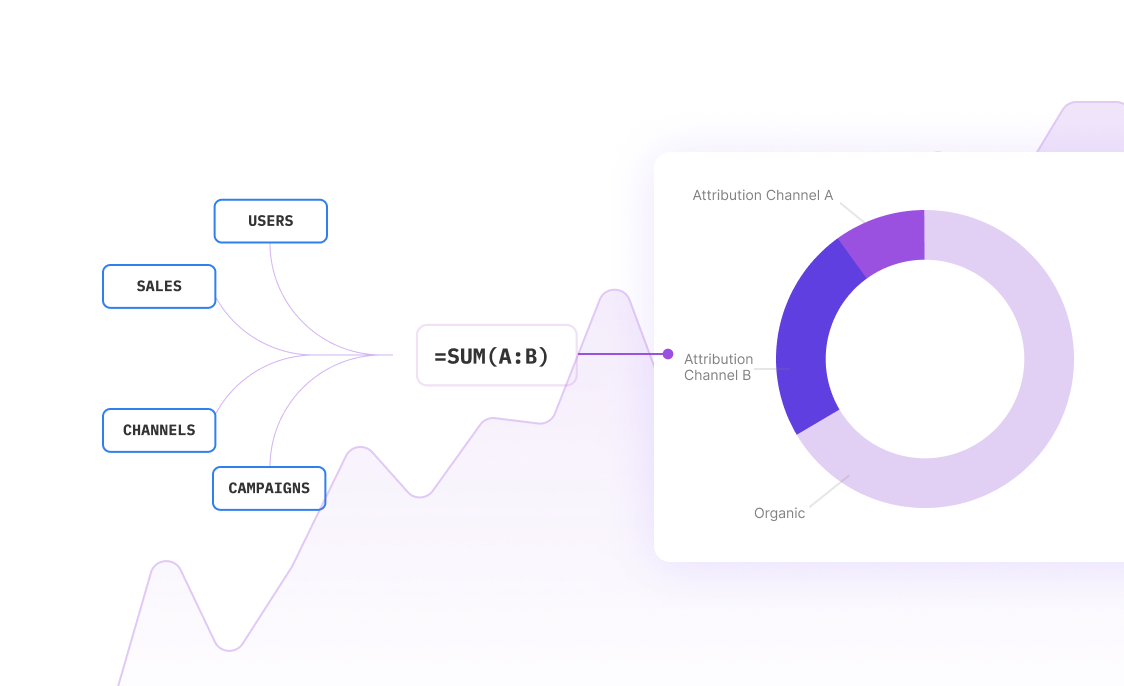

Sourcetable's AI chatbot transforms stackup data into stunning visualizations with a simple conversation. Tell the AI what insights you need, and it automatically generates the most effective charts and dashboards. This conversational approach eliminates the manual chart creation and formatting required in Excel, making tolerance analysis results immediately understandable.

Natural Language Processing Integration

Sourcetable's AI chatbot enables team members to analyze stackup data through natural conversation. Upload your data files or connect your database, then simply ask questions about your tolerance calculations. The AI handles the complex analysis and visualization, letting engineers focus on interpreting results rather than managing spreadsheet functions.

Enhanced Analysis Features

Sourcetable's AI capabilities far exceed Excel's basic functionality. The chatbot can generate sample data, perform complex analyses, and create comprehensive reports through simple text commands. This conversational interface ensures consistent, error-free stackup analysis while dramatically reducing the time engineers spend on manual calculations and formatting.

Benefits of Stack Up Analysis with Sourcetable

Why Stack Up Analysis Matters

Stack Up Analysis ensures proper part fitting, mechanism functionality, and design validation in mechanical assemblies. It predicts assembly variations based on part dimensions, identifies key characteristics, and enables strategic tolerance allocation. This analysis guarantees product quality, performance, and cost-effective manufacturability.

Sourcetable vs Excel for Stack Up Analysis

While Excel can perform stack up analysis, it requires complex functions and formulas that slow down workflow. Sourcetable revolutionizes the process through its AI chatbot interface, letting users communicate their analysis needs in natural language. Simply upload your data and tell Sourcetable what analysis you need.

Enhanced Data Analysis and Visualization

Sourcetable's conversational AI interface eliminates the need for function knowledge or technical expertise. Users can easily request data analysis, generate visualizations, and create comprehensive reports through simple chat interactions. The platform creates professional charts and visualizations based on your verbal or written requests.

Automation and Efficiency

Sourcetable's AI capabilities automate complex stack up analysis tasks through natural language commands. Whether working with uploaded files or connected databases, users can quickly analyze data and generate insights without manual formula creation or chart formatting.

Types of Stack Up Analysis Examples with Sourcetable

Stack Up Analysis calculates cumulative part tolerances in assemblies, analyzing them linearly. Three primary methods are available: Worst-case, RSS (Root Sum of the Squares), and Statistical analysis.

Worst-case Stack Up Analysis

This traditional method calculates absolute upper and lower tolerance limits by placing variables at their extremes. A practical example includes calculating total height variations in stacked disk assemblies.

RSS Stack Up Analysis

RSS analysis employs simplified calculations for tolerances instead of standard deviations. Like the worst-case method, it can analyze stacked disk assemblies but provides more flexible tolerance ranges.

Statistical Stack Up Analysis

This method combines dimensional statistical distributions to predict assembly stackup distances. It offers greater design flexibility compared to worst-case analysis, making it ideal for complex mechanical designs like rotary feeders and magnetoresistive sensors.

Analysis with Sourcetable

Sourcetable's AI chatbot simplifies Stack Up Analysis by allowing users to upload their data files or connect databases directly. Users can perform complex calculations and generate visualizations by simply describing their analysis needs in natural language, eliminating the need for manual formula creation.

Stack Up Analysis Use Cases with Sourcetable

Statistical Tolerance Analysis with AI Assistance |

Use Sourcetable's AI chatbot to analyze manufacturing tolerances from uploaded CSV files or database connections. Simply describe your analysis needs in natural language to generate comprehensive tolerance stack-up calculations. |

AI-Driven Financial Modeling |

Perform stack-up analysis of financial data by conversing with Sourcetable's AI. Upload financial datasets and let the AI generate models that reveal business strengths and weaknesses across multiple operational angles. |

Monte Carlo Simulation Made Simple |

Ask Sourcetable's AI to run Monte Carlo simulations on your data. The AI handles all calculations, including |

Intuitive Multi-dimensional Analysis |

Direct Sourcetable's AI to analyze stack-up effects across multiple dimensions. Generate stunning visualizations and charts that identify cumulative effects by simply describing your analysis needs in plain English. |

Frequently Asked Questions

What is Stack Up Analysis and what is it used for?

Stack Up Analysis is a design tool used to analyze and optimize product design for assembly by calculating the cumulative effects of part tolerances. It ensures smooth assembly on the production floor, product quality, and manufacturability at the right price by helping engineers strategically allocate tolerance budgets.

What are the main methods of Stack Up Analysis?

The two main methods are Worst Case Tolerance Analysis and Statistical Tolerance Analysis. Worst Case Analysis uses addition and subtraction to ensure 100% parts assembly but requires tight tolerances and increases costs. Statistical Analysis allows for increased component tolerance limits and is typically more cost-effective.

How can I perform Stack Up Analysis in Sourcetable?

You can perform Stack Up Analysis in Sourcetable by uploading your data file or connecting your database and using the AI chatbot interface. Simply tell the AI what analysis you want to perform, and Sourcetable will help you calculate tolerances, analyze the results, and create visualizations of your stack up analysis.

Conclusion

Stack Up Analysis helps engineers ensure parts fit together properly through tolerance calculations in a spreadsheet. While Excel enables Stack Up Analysis through manually created tolerance stack up spreadsheets, Sourcetable offers an AI-driven alternative that eliminates the complexity. Instead of wrestling with Excel formulas and functions, you can simply tell Sourcetable's AI chatbot what analysis you need, and it will handle the calculations, data visualization, and insights automatically. To streamline your Stack Up Analysis workflow with conversational AI, try Sourcetable at https://app.sourcetable.cloud/signup.