Introduction

Tolerance Analysis verifies dimensional variations in mechanical parts and assemblies through tolerance stack-up calculations. While traditionally performed in Excel spreadsheets, modern tools offer more efficient solutions. Autodesk Inventor Tolerance Analysis automates these calculations, analyzing geometric tolerances and clearances to reduce manufacturing issues.

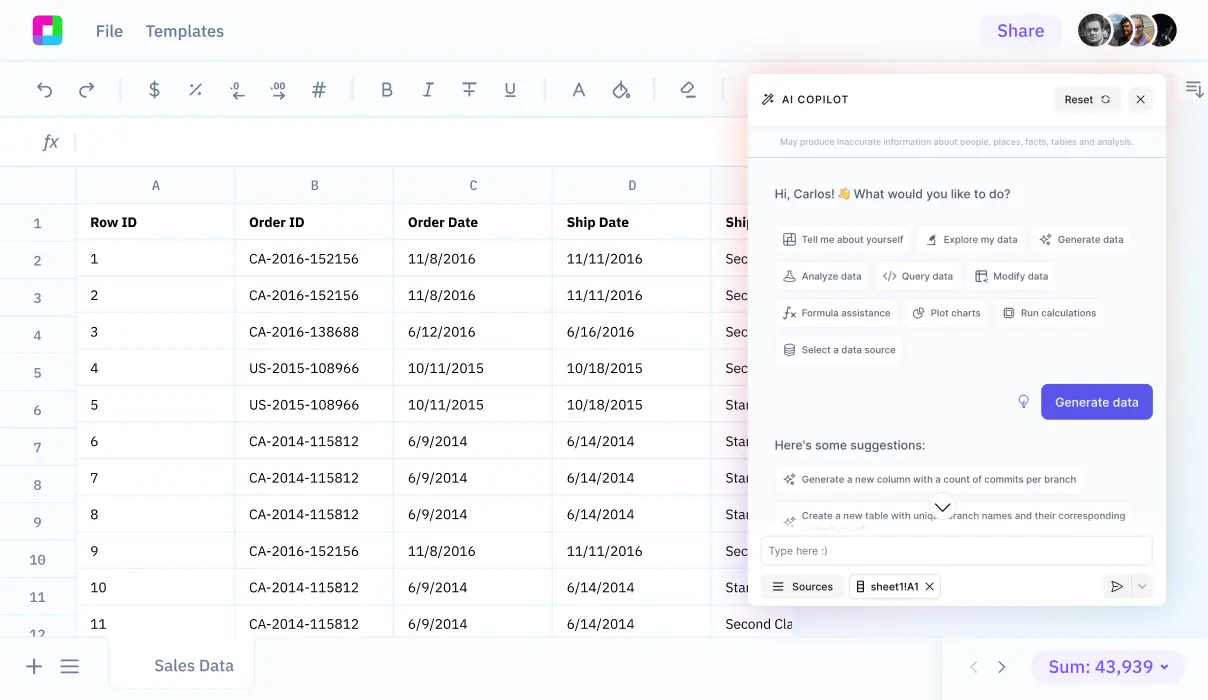

Sourcetable emerges as an innovative AI-powered spreadsheet that transforms the analysis process. Through natural language interaction with its AI chatbot, users can analyze tolerance data, generate visualizations, and process files of any size without requiring Excel expertise. Users can upload spreadsheet files or connect databases for seamless analysis.

In this guide, we'll explore how Sourcetable's AI capabilities transform Tolerance Analysis, which you can experience at https://app.sourcetable.cloud/signup.

Why Sourcetable Is Superior for Tolerance Analysis

Sourcetable revolutionizes tolerance analysis by replacing complex Excel functions with an intuitive AI chatbot interface. While Excel requires manual setup of N-1 independent relative dimensions and complex math functions, Sourcetable lets you describe your tolerance analysis needs in plain language.

Enhanced Analysis Capabilities

Excel's tolerance analysis relies on manual dimensional calculations and user-defined data types. Sourcetable's AI chatbot can automatically analyze your uploaded spreadsheets or database data, making complex tolerance calculations effortless. Simply tell the AI what analysis you need, and it handles the calculations instantly.

Improved Visualization and Reporting

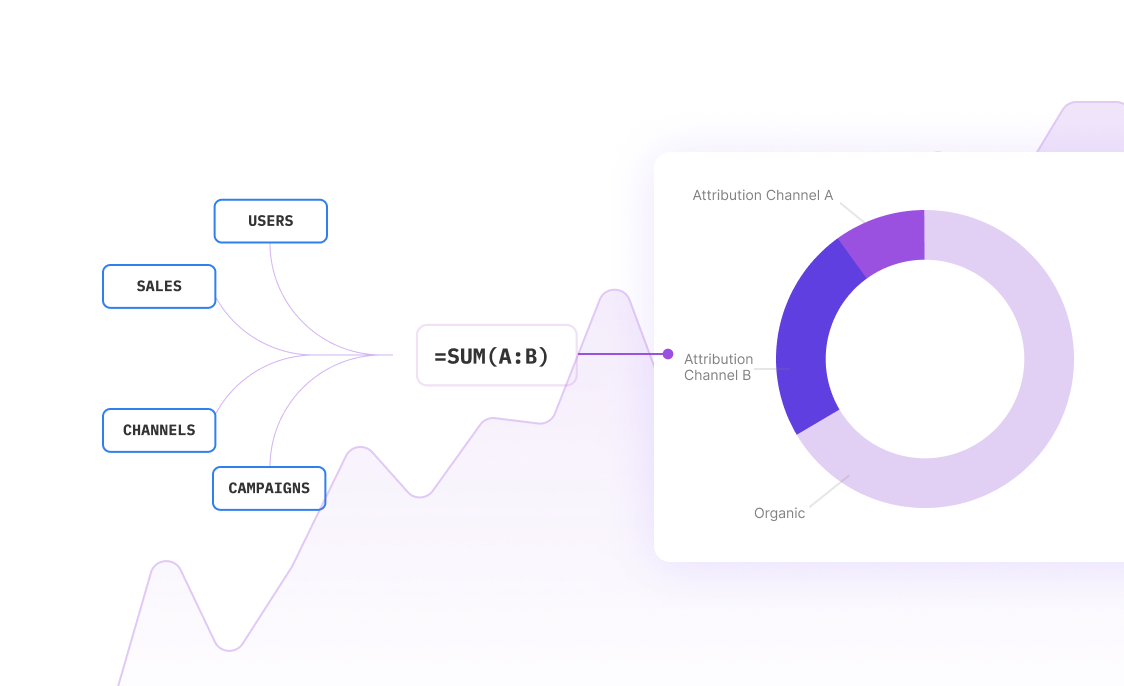

Unlike Excel's manual charting process, Sourcetable's AI can instantly generate stunning visualizations from your tolerance data. Users can request dashboards, charts, and reports through natural conversation, making it easy to identify critical tolerance contributors and dimensional variations. This enhanced visibility leads to better manufacturing decisions.

Manufacturing Benefits

Sourcetable's AI-powered analysis helps manufacturers reduce scrap rates, minimize assembly issues, and optimize processes more effectively than Excel's manual methods. The ability to interact with tolerance data through natural language makes advanced analysis accessible to analysts, operators, and finance teams without requiring spreadsheet expertise.

Benefits of Tolerance Analysis with Sourcetable vs Excel

Why Tolerance Analysis Matters

Tolerance analysis ensures manufactured parts fit together properly across suppliers, machines, and production times. It helps engineers optimize designs by balancing fit and performance with production costs. Early problem identification through tolerance analysis prevents expensive rework during production and reduces prototype needs, saving time and money.

Sourcetable's AI-Driven Analysis

Sourcetable's AI chatbot interface eliminates the complexity of traditional spreadsheet functions for tolerance analysis. Users simply describe their analysis needs in natural language, and Sourcetable performs the calculations automatically. The platform handles data of any size through file uploads or direct database connections, making complex analysis accessible and efficient.

Visualization and Reporting Advantages

Sourcetable simplifies data visualization through natural language commands. Users can request specific charts and visualizations without manual configuration, transforming complex data into clear insights. The AI understands context and automatically suggests the most effective visualization methods for your data.

AI-Powered Efficiency

Unlike Excel's function-based approach, Sourcetable's conversational AI interface streamlines the entire analysis process. Users can create spreadsheets from scratch, generate sample data, and perform complex analyses through simple chat interactions. This natural language approach significantly reduces analysis time and eliminates the learning curve associated with traditional spreadsheet tools.

Types of Tolerance Analysis with Sourcetable

Sourcetable, an AI-powered spreadsheet alternative to Excel, simplifies tolerance analysis through natural language interaction. Simply upload your tolerance data files or connect your database, then tell Sourcetable's AI what analysis you need. The AI automatically handles the complex calculations and analysis tasks.

Common Analysis Examples

Engineers can analyze various mechanical systems including clamping mechanisms, springs, levers, and clearance measurements. Rather than manually configuring formulas, simply describe your analysis needs to Sourcetable's AI.

Statistical Analysis Capabilities

Through AI-powered analysis, Sourcetable can perform advanced statistical calculations, model assembly processes, and understand manufacturing variation impacts. The AI assistant guides you through the entire analysis process, from data input to results interpretation.

Sourcetable's AI capabilities help engineers quickly quantify total system tolerances and validate that designs can be manufactured within specified requirements, all through simple conversation with the AI.

Tolerance Analysis Use Cases with AI Spreadsheets

Design Optimization |

Import CAD data via CSV files and use AI-guided analysis to optimize manufacturing tolerances before production. Natural language commands simplify the process of calculating variations and determining optimal specifications. |

Quality Improvement |

Use conversational AI to perform worst-case and statistical analyses, improving manufacturing yield and product quality. Generate visualizations instantly through simple prompts to identify critical tolerance patterns. |

Cost Reduction |

Leverage AI-powered analysis of tolerance data to identify where specifications can be relaxed. Generate instant insights and visualizations to balance manufacturing costs with product functionality. |

Prototype Reduction |

Upload prototype specifications and use AI to predict fit issues before physical production. Quick iteration through natural language commands accelerates development and reduces the need for physical prototypes. |

Frequently Asked Questions

What is Tolerance Analysis and why is it important?

Tolerance Analysis is a systematic method that examines all relevant tolerances in a system to determine if a design can be built with specified tolerances. It's important because it ensures parts fit together properly, helps determine acceptable geometric variations, and saves time and money by identifying potential fit issues before production. It also helps balance fit and performance with production costs while preventing expensive rework and warranty claims.

How is Tolerance Analysis performed?

Tolerance Analysis is performed in three main steps: Prepare, Stack, and Adjust. It's typically done using a spreadsheet-based stack-up analysis, and should be conducted both before and after detailed design. The analysis examines the critical dimensions and tolerance chains to determine the contribution of various tolerances in the system.

How can Tolerance Analysis be done in Sourcetable?

Tolerance Analysis can be easily performed in Sourcetable by leveraging its AI-powered interface. Simply upload your tolerance data through a CSV or Excel file, or connect your database, and tell Sourcetable's AI chatbot what analysis you want to perform. The AI will help you analyze tolerance chains, calculate capabilities, and create visualizations of your results without needing to work with complex spreadsheet functions or formulas.

Conclusion

While Excel can perform tolerance analysis, Sourcetable offers an AI-powered alternative that streamlines the process through natural language interaction. Sourcetable can execute worst-case tolerance analysis, root-sum-squares tolerance analysis, and Monte Carlo simulations to determine error distributions. This AI-powered spreadsheet lets you upload your data or connect your database, then simply tell its chatbot what analysis you need - no Excel skills required.

Whether analyzing voltage divider circuits or performing component tolerance stack-ups, Sourcetable's conversational AI interface makes complex tolerance calculations accessible to everyone. The platform can generate sample data, create visualizations, and perform advanced analysis based on simple natural language requests. Ready to modernize your tolerance analysis workflow? Try Sourcetable today.